One of the key benefits of automatic electrical winch is their ability to work automatically, without requiring manual intervention. This means that they can be controlled remotely or programmed to stop automatically once they have reached a certain load or distance. This makes them an ideal choice for applications where safety and efficiency are top priorities.

For example, they can be designed to work in extreme environments, such as deep sea or arctic conditions, and can be equipped with additional safety features, such as automatic brakes or overload protection.

Another benefit of automatic electrical winch is their ease of use and maintenance. Unlike hydraulic winches, which require regular maintenance and can be messy to operate, automatic electrical winches are clean and easy to operate. They also require minimal maintenance, which makes them a cost-effective solution in the long run.

1 Technical specification

| 1) Capacity: | ≥300m; |

| 2) Load tension: | ≥100kg; |

| 3) Tension and retraction: | ≥100kg; |

| 4) Size approx.: | <1050x1000x950 |

| 5) G.W.: | ≤60kg |

| 6) Power supply: | 220V |

| 7)Power: | 750w,Servo |

| 8)Retraction speed: | 0-20m/min |

| 9) Work temperature: | -20℃-+80℃ |

| 10)Cores of slip ring: | 2* F/O 2* Electrical |

| 11)Rated current (Slip ring): | 2 core * 10A |

| 12)Insulation resistance(Slip ring) | 500MΩ |

| 13)Work life (Slip ring): | 1,000,000 rotary |

| 14)Waterproof rank (Slip ring): | IP51 |

| 15)Work temperature (Slip ring): | -20℃-+80℃ |

| 16)Material ( Slip ring): | Stainless steel 316L |

| 17)Weight (Slip ring): | ≤1.0kg |

| 18)Interfaces: | 1 unit; |

| 19)Cores of interface: | 2*F/O 2* Electrical |

| 18)Waterproof rank (Interface): | IP68 |

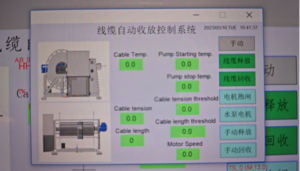

2 Main function

- Reeling control;

- Self stowing mooring;

- Brake;

- Communication;

- Length and Tension display;

3 Interfaces

There are 3 interfaces as follow:

1) Physical interface: Waterproof junction box;

Transmission:Single and power supply between Cabling and Slip ring;

- Interface 2:UNIR18M-2S2Watertight connector;

Transmission:Uplink signal from winch to shore equipment, Downlink power supply;

- Interface 3:UNIR18M-2S2Watertight connector;

Transmission: Uplink signal from cabling to underwater end,Downlink power supply;

Facebook LinkedIn